Production information

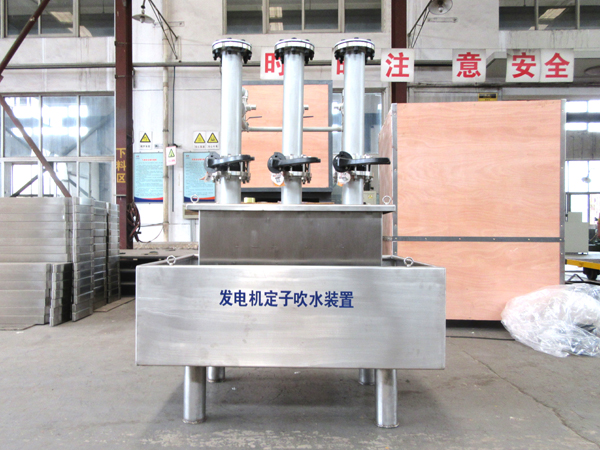

When the generator is shut down for maintenance, the inside of the generator stator contains water. The stainless steel corrugated pipe on the generator stator water blowing device is connected to the flange interface at the top of the generator through a variable diameter flange, and nitrogen is introduced to fill the inside of the generator stator with gas. After the gas pressure reaches 0.28-0.32MPa, the butterfly valve on the exhaust circuit is opened, and the gas pressure inside the stator is instantly released, Allow the moisture inside the generator stator to be discharged through gas pressure. Repeatedly add nitrogen to the inside of the generator stator, open the butterfly valve on the steam side, and release pressurized nitrogen from the excitation side to blow out moisture. Open the butterfly valve on the excitation side, and release pressurized nitrogen from the steam side to blow out moisture. This repeated blowing can blow out the moisture inside the stator of the generator.

All products are made of 304 stainless steel, with a beautiful appearance.