Production information

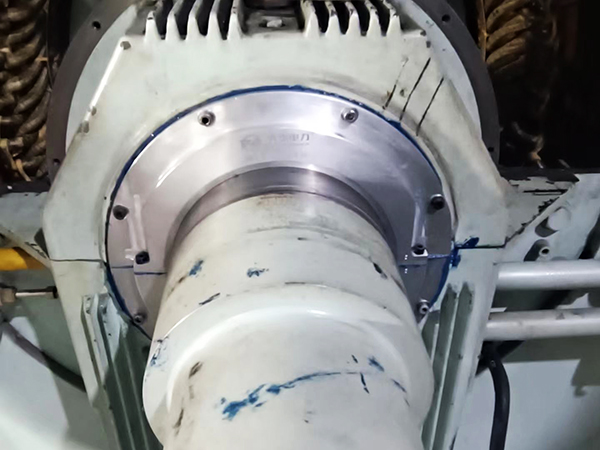

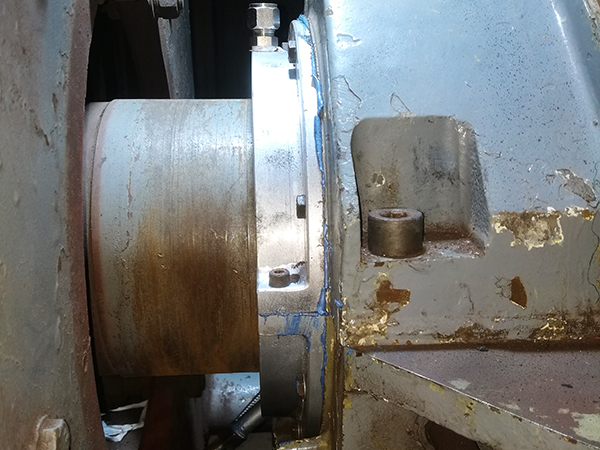

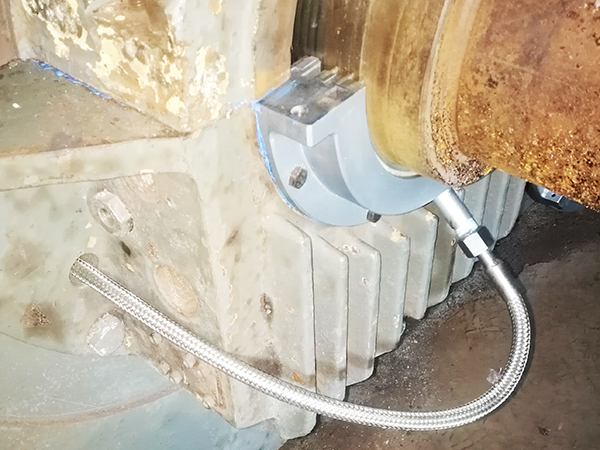

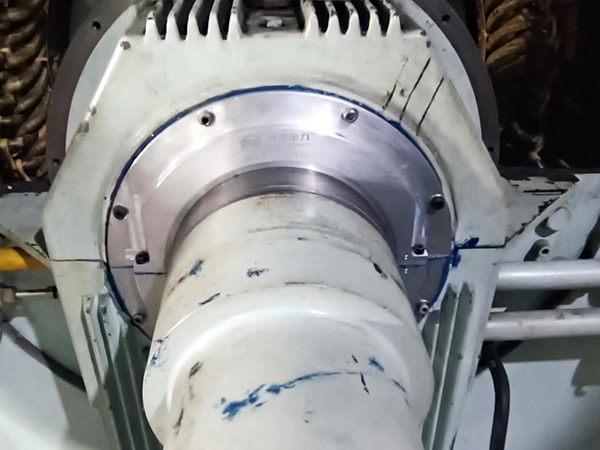

The main principle of the XQYD type new gas-wall sealing oil baffle is to allow dry compressed air to enter the air chamber of the oil baffle, and then exhaust through the air grooves on the air chamber. This causes the compressed air to form a ring-shaped air wall around the shaft diameter. The air wall completely wraps around the shaft diameter, preventing external steam from entering the bearing housing and also preventing the splashed lubricating oil in the bearing housing from approaching the copper teeth of the oil baffle. The new gas-wall sealing oil baffle completely solves problems such as water ingress into the lubricating oil and emulsification of the lubricating oil by steam. The new gas-wall sealing oil baffle adopts a non-contact air sealing method, eliminating the problem of carbon deposition at the tips of the oil baffle teeth. Problems such as shaft wear and unit vibration caused by carbon deposition on the oil baffle will no longer occur. The new gas-wall sealing oil baffle has six major advantages: 1. Safe and reliable; 2. Energy-saving and environmentally friendly; 3. Cost reduction; 4. Low failure rate; 5. Long service life; 6. High economic benefits.